Links:https://innovtechtw.en.taiwantrade.com/newslist

Optical bonding is the process of gluing the touchscreen glass to the LCD cell in order to completely fill the air gap between them. This is done to improve overall performance, decrease the total display weight, and make the touchscreen sturdier.

Traditionally, interactive displays are attached to LCD cells with adhesive tape by the edges of the screen glass. This creates an air gap between the LCD cell and the screen glass that is detrimental to the performance of the display no matter how thin the air gap is. The gap results in setbacks which include a more fragile screen glass, loss of touch accuracy, and a narrower viewing angle, among others.

There are many benefits that come with the optical bonding of a display, all which enhance the performance of the interactive display in varying conditions and allow a greater range of application needs to be met. Here are the top 6 benefits:

There are many benefits that come with the optical bonding of a display, all which enhance the performance of the interactive display in varying conditions and allow a greater range of application needs to be met. Here are the top 6 benefits:

1. Greater durability

The optical bonding process better protects both the cover glass and LCD cell from shock, as the hardened adhesive behind the glass acts as a shock absorber. Shake and shocks are less likely to damage the display and glass, making it an important benefit for transportation applications. In the unlikely event that the glass is damaged, shards of broken glass will remain stuck to the optical adhesive, making it an important benefit for safety reasons in classrooms and meeting rooms.

2. Improved viewing experience

2. Improved viewing experience

An optically bonded display eliminates the internal reflection between the screen glass and the LCD cell. This results in improved contrast, which enables the display to be better seen in brighter environments. Additionally, the elimination of internal reflection provides a wider viewing angle, allowing the display to be seen more clearly from wider angles in bigger rooms. Whether you have student desks at the front corners of the classroom, or you have to cram seats up the front sides of the meeting room, everyone will be able to see the screen clearly without reflection.

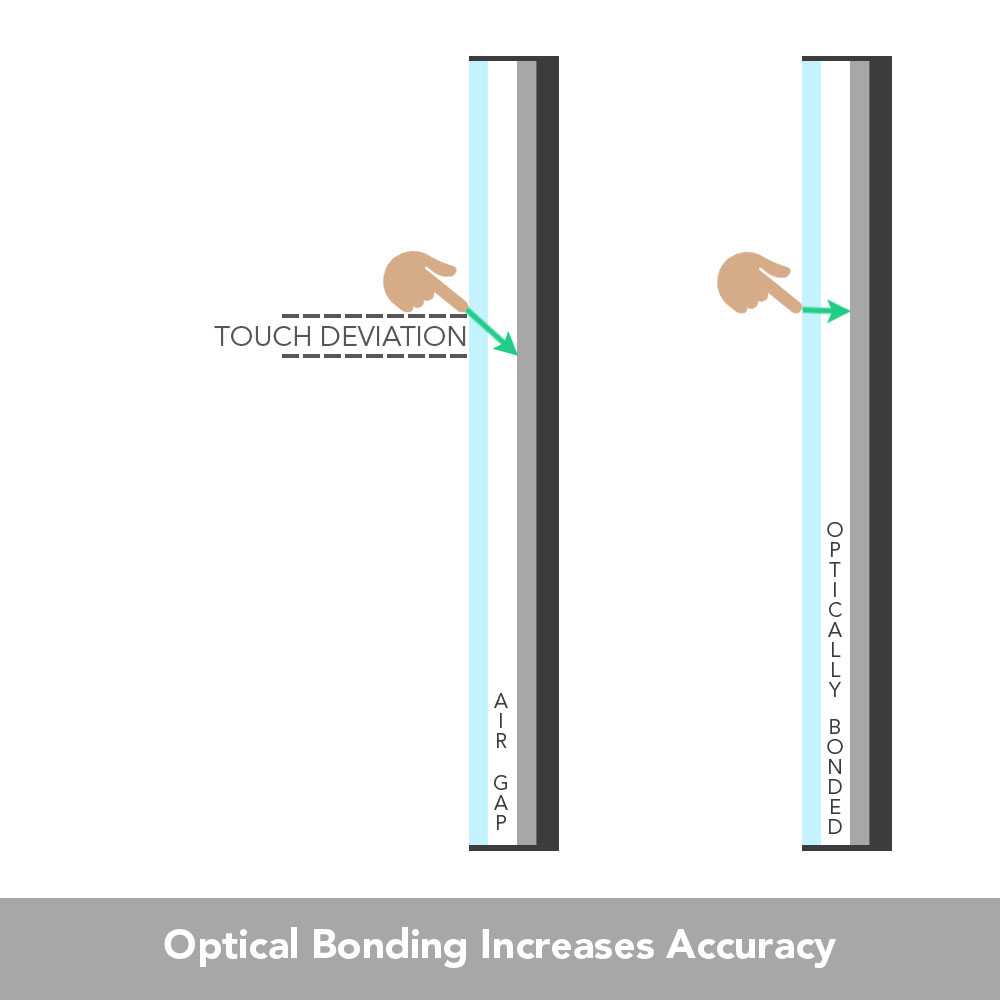

3. Improved touch experience

Optical bonding reduces parallax, the refraction angle of light which makes the physical location of a pen or finger on the glass appear to be different from the corresponding point on the LCD, depending on your line of sight. This leads to inaccuracy of touch and a poor user experience. Optical bonding removes the air gap, which eliminates parallax to give you the most accurate touch, for the most natural and reliable experience.

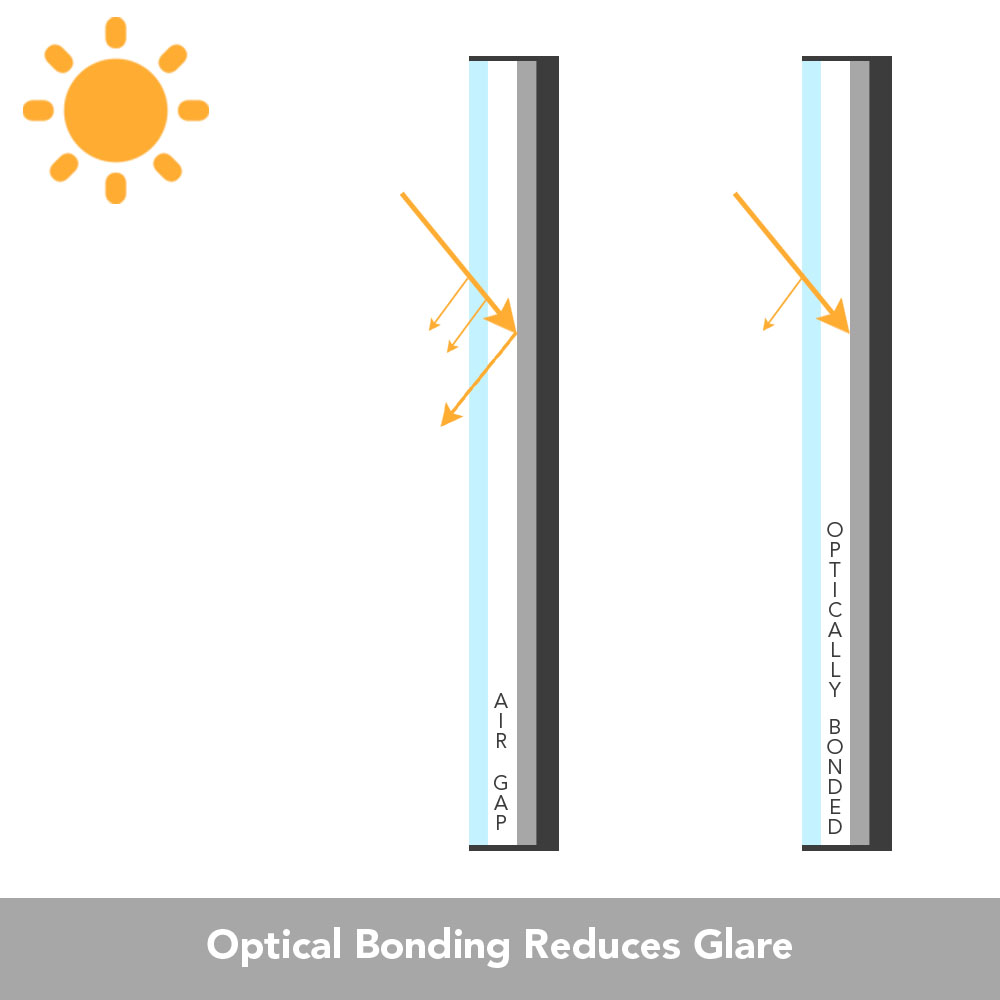

4. Reduced Glare

4. Reduced Glare

The same principle is applied when an external source of light hits the screen. With an non-bonded screen, the gap between the glass and LCD module creates opportunities for refraction which bounces external light back off the screen to the viewer as glare. When bonded together the light passes through the bonded layers and is absorbed somewhat into the screen. Optical bonding is therefore important in making screens sunlight readable.

5. Increase Accuracy

A touch monitor with optical bonding maintains a more accurate touch response because the pressure is maintained through the substrate, rather than being delayed by a gap

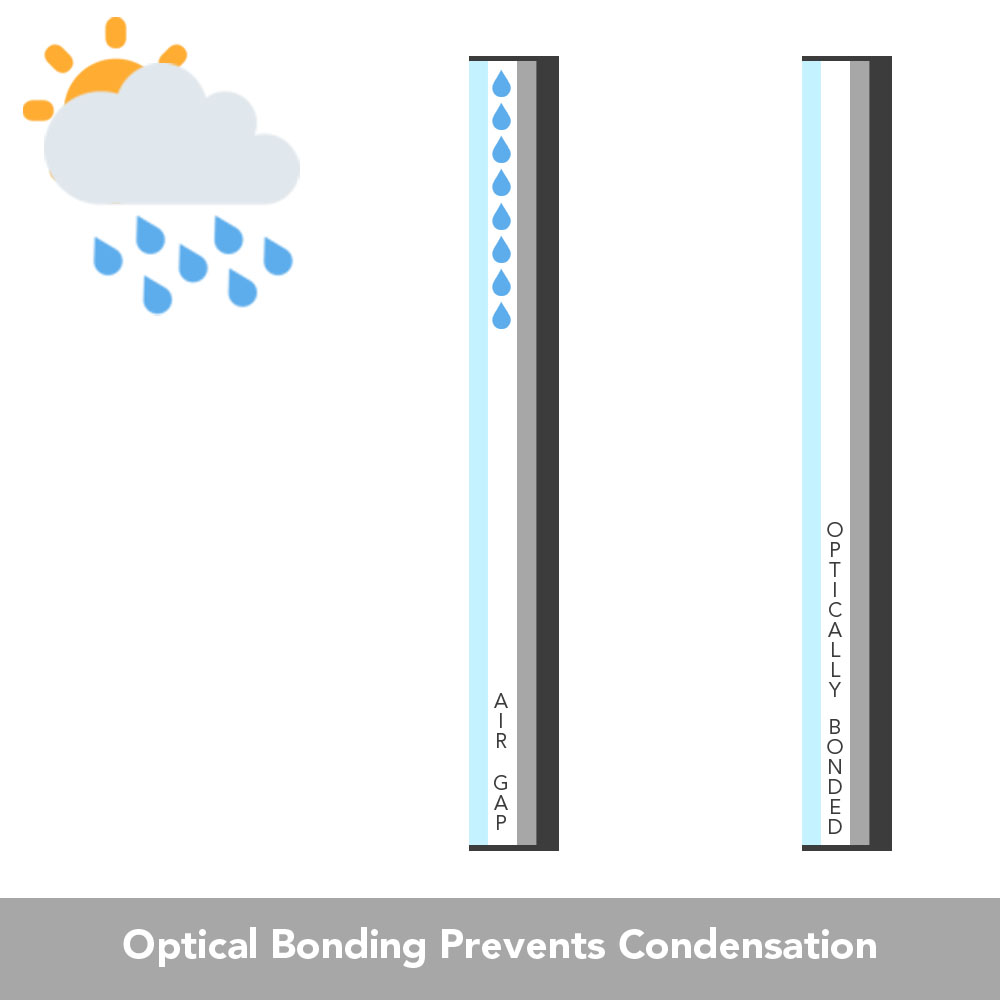

6.Prevent Condensation

The most obvious benefit to adding a resin bonding layer between the glass and LCD module is that it physically prevents dust and liquid ingress from getting between the two. The quality of manufacturing means that dust and water isn’t a big problem for screens in standard environments. What can be a problem however is condensation getting between the glass and LCD panel in environments with wide temperature ranges or fluctuating humidity. Condensation can cause screens to become foggy from moisture that penetrates the air gap. Again, the physical filling of the gap prevents this problem from arising. Optical bonding should therefore be considered for any outdoor application as well as indoor applications where consistent temperatures aren't maintained.